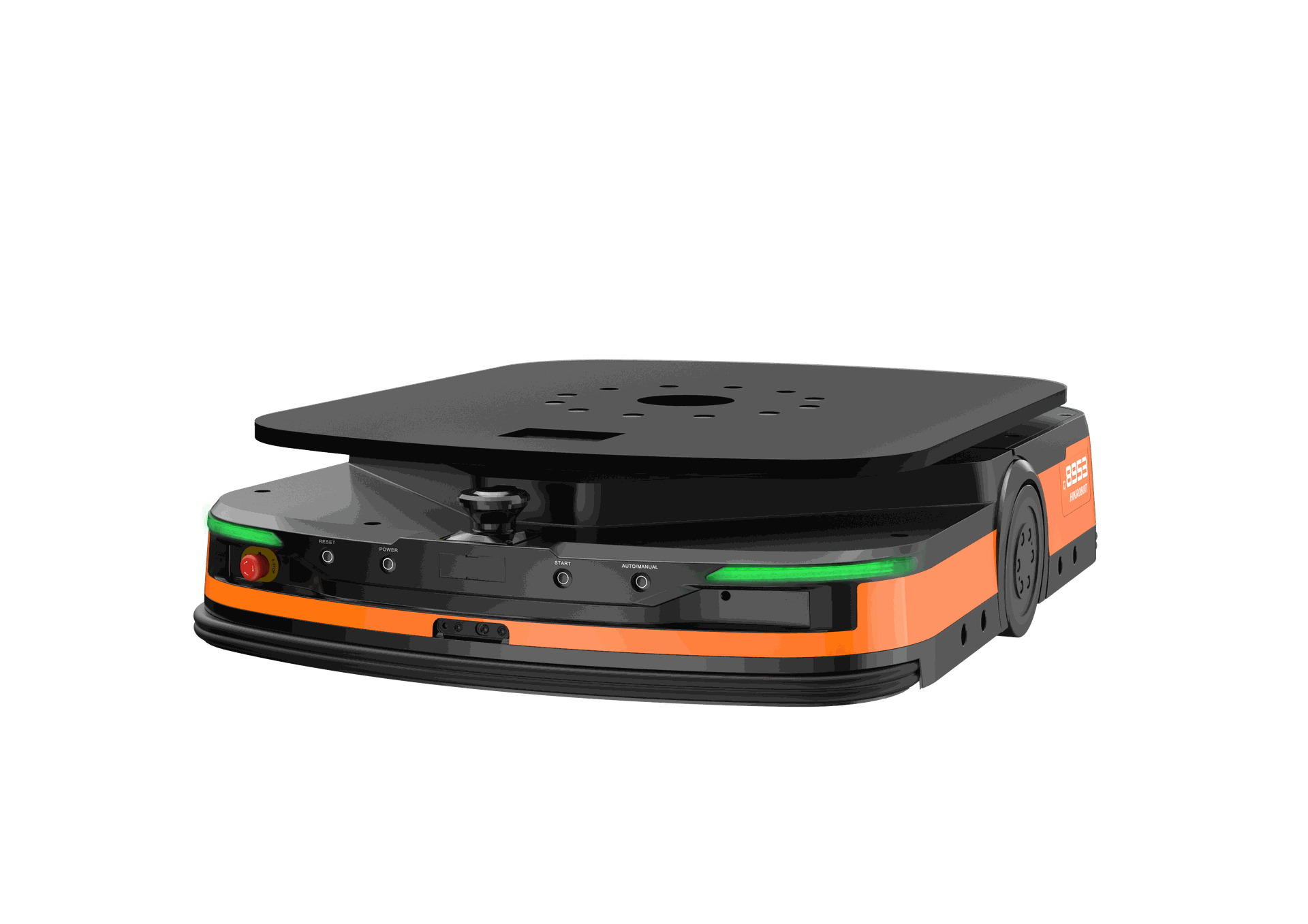

Hikrobot Mobile Robots

Revolutionize your internal logistics

Focusing on the core technology of robots, Hikrobot provides customers with safe and reliable intelligent mobile robot products and systems, and build smart internal logistics solutions in industrial factories.

Datasheets Contact us

Warehousing & Distribution

Manufacturing

Healthcare

Logistics & Transportation

What

Are Mobile Robots?

A mobile

robot is a type of robot that can understand and move through its environment

independently, or through tracks or predefined paths.

An autonomous guided vehicle, or AGV for short, is a type of vehicle that can move around a factory or warehouse carrying things from one place to another.

In a large warehouse with strong logistic needs, Instead of people having to push carts or drive forklifts to move things around, you could have these AGVs doing the job. They can be programmed to pick up items from one spot and take them to another spot all on their own.

These AGVs are really handy in industries because they can help with tasks like transporting materials or products safely and efficiently. They can also work around the clock without needing breaks, making them quite useful in places where things need to keep moving smoothly all the time.

What are mobile robots used for?

These types of mobile robots help several industries optimizing their logistics, promoting the productivity cost-effectively. Some great examples are:

Manufacturing: In manufacturing plants, AGVs are commonly used to transport materials and components between different production stations. For example, they might carry raw materials to the assembly line or move finished products to the warehouse for shipping.

Warehousing and Distribution: In large warehouses and distribution centers, AGVs play a vital role in moving goods efficiently. They can navigate aisles and shelves to retrieve items for order fulfillment and then transport them to the packing area or loading docks.

Logistics and Transportation: AGVs are utilized in logistics and transportation operations to streamline processes such as loading and unloading cargo containers at ports or moving goods within airport terminals.

Healthcare: In hospitals and healthcare facilities, AGVs are used to transport medications, supplies, and equipment between different departments. They can help optimize workflows and reduce the time spent by staff on logistical tasks, allowing them to focus more on patient care.

Retail: AGVs are increasingly being adopted in retail settings to automate tasks such as restocking shelves and moving inventory within warehouses or stores. This automation helps retailers manage inventory more efficiently and improve overall operational productivity.