ZTEC, as a supplier of ROKAE and the welding solutions and robots is impressed by the technological innovation that has recently strengthened ROKAE as a key player in the robotics field. We are increasingly looking forward to provide the Nordic and Baltic markets with the EasyWeld solution that ROKAE has succesfully developed for the Eastern and Western industries.

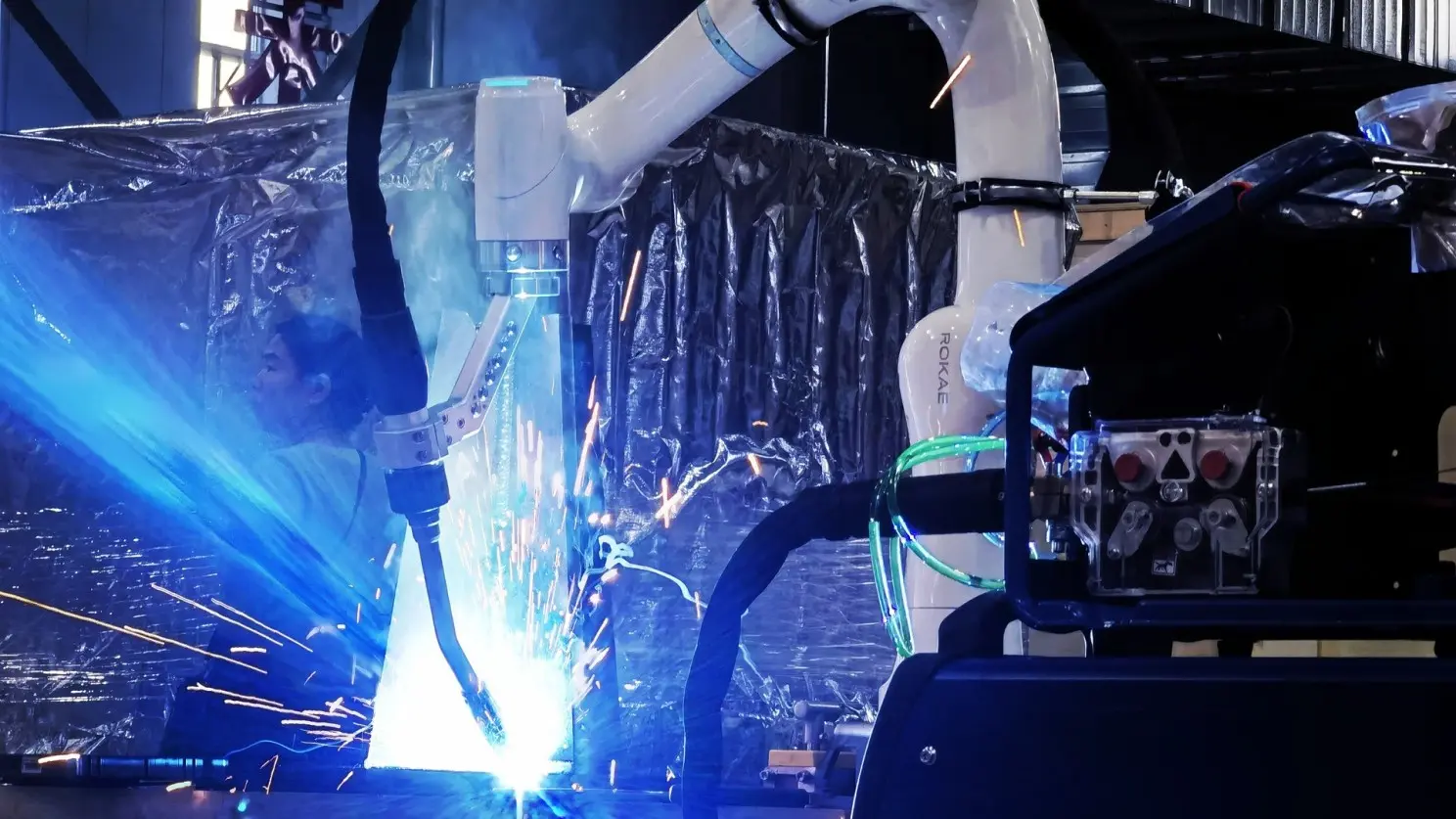

The 2025 China Construction Machinery and Agricultural Machinery Smart Manufacturing Conference was held successfully in Nanjing recently. As a leading player in the field of collaborative welding, ROKAE Robotics appeared stunning with its intelligent welding solutions, joining industry peers to explore pathways for smart manufacturing upgrades.

During the conference, Ma Jiafeng, Customer Director of the Welding Industry Department at ROKAE Robotics, delivered a speech titled "Expanding and Deepening in the Major Arena, Intelligently Ushering in a New Future for Welding." He systematically shared ROKAE's strategic layout of driving the intelligent upgrade of welding robots through technological innovation and showcased the company's breakthrough achievements in the field of collaborative welding. He pointed out that from this new starting point, ROKAE will continue to leverage its strengths in collaborative welding technology, further expand application scenarios, and work hand-in-hand with partners to create a new future for welding.

Outstanding Products: "Full-Joint Force Control" Flexible Collaborative Welding Robots

With its core "Full-Joint Force Control" technology, ROKAE has developed a comprehensive new-generation product matrix of flexible collaborative welding robots. The five major product features directly address industry pain points, providing efficient solutions for high-mix, low-volume welding production:

Ultra-Compliant Drag Teaching:

Each joint of ROKAE's flexible collaborative welding robots is equipped with a built-in high-precision torque sensor. With less than 1N of force, they can be dragged easily, precisely, and smoothly, making teaching effortless even for large payloads. Models with large reach can be dragged easily, enabling precise starting and crater filling point alignment without external joysticks.

Singularity Avoidance:

Utilizing self-developed singularity avoidance algorithms, ROKAE robots ensure precise TCP positioning and stable operating speed while intelligently avoiding singularities, significantly enhancing motion continuity and stability, and preventing abnormal stops.

High Path Accuracy & Absolute Accuracy:

Based on high-order dynamics algorithms and TrueMotion path planning technology, ROKAE robots achieve an absolute accuracy of 0.3mm and a path repeatability better than 0.4mm, ensuring welding consistency.

The newly upgraded vibration suppression algorithm ensures extremely high stability even at low speeds, achieving "zero" overshoot and eliminating low-speed jitter, solving challenges in welding path precision and jitter control.

High-Precision Torch Weaving:

Leveraging ROKAE's self-developed high-order dynamics algorithms and high-precision compensation technology, ROKAE robots achieve high-precision weaving motions along the X, Y, and Z axes with errors less than 0.6mm, ensuring accurate and stable torch posture.

High Protection & High-Temperature Resistance: The robots utilize motion planning under dynamic constraints for greater stability and durability. Paired with the MCC series high-protection control cabinet, they boast an IP54 protection rating and have passed whole-machine tests in 55°C high-temperature environments, making them suitable for various demanding welding conditions.

Intelligent Welding System: Enabling "Easy Welding" for High-Mix, Low-Volume Production

Beyond robust hardware, ROKAE has built a customized collaborative welding system centered on "intelligence" and "ease of use," continuously optimizing welding processes, lowering the barrier, and achieving the perfect unity of "welding well" and "welding easily."

Arc Welding Graphical Programming Software: Master in 2 Hours, Farewell to "Programming Dependence":

Deeply involved in frontline welding, the ROKAE team precisely identified end-user needs and pain points. Based on fully self-developed core robot technologies, they launched a new collaborative arc welding graphical programming software package. Featuring a fully Chinese graphical interface and guided programming design, users can get started within 2 hours and become proficient within a day. The software's clear logic and simple operation significantly lower the skill threshold for welding tasks and fully covers advanced arc welding functions like Arc Tracking, External Axis Synchronization, Multi-Layer Multi-Pass, real-time line laser tracking, and 3D vision-based teaching-free welding, meeting diverse welding needs.

Smart Drag Teaching Handle: All-in-One Control, Simplifying Operation:

ROKAE's welding smart drag teaching handle not only has a clear program display interface but also integrates process parameter setting, quick point interpolation, and simulated/actual welding switching functions. It significantly enhances operational convenience and human-robot interaction efficiency, making teaching simpler and more efficient.

Arc Tracking Function: Real-Time Correction, Ensuring Precision and Consistency:

ROKAE's collaborative arc welding Arc Tracking function supports linear/circular paths and flat/vertical welding. The system intelligently recommends arc tracking parameters with adjustable values. The minimum tracking current is as low as 110A, effectively coping with workpiece deviation and deformation issues, ensuring path accuracy and neat, aesthetically pleasing welds.

For medium-thick plate vertical welding, a spatial L-type weaving pattern allows the wire to reach the weld root for more stable formation. Coupled with the Arc Tracking function, only rough teaching of the weld end point is needed to achieve real-time correction.

External Axis Synchronization: Precise Coordination, Covering Large Spaces:

Featuring high-precision synchronous control of external axes, users can control the forward/reverse movement of external axes with a single click within the arc welding software interface. The operation is simple, the response precise, easily covering large workpieces or multi-station production lines, enhancing overall line efficiency.

Multi-Layer Multi-Pass Function: Automatic Bead Sequencing, Improving Weld Quality:

Addressing the needs for large fillet welds, large grooves, and high-strength welds on medium and thick plate workpieces, ROKAE developed the Multi-Layer Multi-Pass function. Its setup logic is simple; users only need to input the offset, and the system automatically sequences the weld beads. It also supports individual parameter modification and torch angle adjustment for any specific weld pass, greatly enhancing process adaptability and ensuring the quality of medium and thick plate welding

Case Study: Multi-Sector Deployment Validates Welding Value

Centered on its self-developed "Full-Joint Force Control" flexible collaborative welding robots and combined with the intelligent welding software system, ROKAE offers intelligent welding solutions that enable flexible smart manufacturing for high-mix, low-volume welding tasks.

Currently, ROKAE's welding solutions have been applied in leading enterprises across sectors such as construction machinery, shipbuilding and offshore engineering, and power equipment construction. They have significantly reduced reliance on specialized welders, improved welding quality consistency, and demonstrated excellent return on investment. ROKAE continues to deepen its expertise through both technology and application scenarios, aiding Chinese manufacturing in moving towards a new, smarter, more flexible, and more efficient future for welding.